Plastic Properties Tables

-

Wear Resistance of PlasticsOpen or Close

The rating that appears in this table refers to the wear properties of the material in a bearing or bush application, and is normally tested using a Pin-on-Disc wear test. It should be noted that this data does not refer to the abrasion properties of the material, which is normally tested by using a Sand-Slurry test, which provides the abrasion resistance of the material when particles rub or slide over the material. The plastic wear resistance chart ranks our materials out of 20 = best wearing. This comparison is done at ambient conditions. It is important to note that at elevated Temp different products may perform differently in respect to the ranking shown here. Refer to Dotmar technical staff for assistance.

Product Product Type Value Ertalyte TX PETP Polyester 20 Techtron HPV PPS PS Polyphenylene Sulphide 20 Duratron T4301 & T4501 PAI PAI Polyamide-imide 20 Ketron PEEK-HPV PEEK Polyetheretherketone 20 Duratron T4203 & T4503 PAI PAI Polyamide-imide 19 Nylatron 703XL Nylon 19 Ketron PEEK-100 PEEK Polyetheretherketone 19 Ertalyte PETP Polyester 19 Orkot C320 TLG Orkot 19 Orkot TLM (Marine) Orkot 19 Ertalon LFX Nylon 18 Duratron PBI PBI Polybenzimidazole 18 Ketron PEEK-CA30 PEEK Polyetheretherketone 18 Nylatron 703XL Nylon 18 Orkot TXM (low friction) Orkot 17 Nylatron GSM Nylon 17 Ketron PEEK-GF30 PEEK Polyetheretherketone 17 Nylatron GS Nylon 17 Duratron T5530 PAI PAI Polyamide-imide 17 Ertalon 6XAU+ Nylon 16 Ertalon 6SA Nylon 16 Ertalon 66SA Nylon 16 Ertalon 6PLA Nylon 16 Ertalon 4.6 Nylon 16 Nylatron MC901 Nylon 16 Ertalon 66GF-30 Nylon 15 Ertacetal C Acetal 14 Polystone Matrox PE Polyethylene 14 Orkot C321 TL Orkot 13 Tetron HG PTFE Polytetrafluoroethylene 10 Tetron S PTFE Polytetrafluoroethylene 9 Tetron B PTFE Polytetrafluoroethylene 9 Tetco V PTFE Polytetrafluoroethylene 9 Tetron C PTFE Polytetrafluoroethylene 9 Tetron LG PTFE Polytetrafluoroethylene 8 Tetron GR PTFE Polytetrafluoroethylene 10 Tetron G PTFE Polytetrafluoroethylene 10 Tetron BL PTFE Polytetrafluoroethylene 10 Polystone M-Slide PE Polyethylene 12 Polystone Ezyslide 78 PE Polyethylene 12 Polystone Ultra PE Polyethylene 12 Polystone 7000 PE Polyethylene 12 Polystone 7000SR PE Polyethylene 12 Polystone M-Flametech AST PE Polyethylene 12 Polystone 8000+ PE Polyethylene 12 Polystone P7000AST PE Polyethylene 12 Polystone Fender PE Polyethylene 12 Symalit PVDF PVDF Polyvinylidenefluoride 7 Polystone 500 PE Polyethylene 7 Polystone PG100 PE Polyethylene 6 Polystone 300 PE Polyethylene 6 Playtec PE Polyethylene 6 PVDF Polyvinylidenefluoride 5 Trovidure EN PVC Polyvinylchloride 4 Polystone PP PP Polypropylene 4 PVC Polyvinylchloride 3 Polyurethane Urethane NA Acrylic Polymethylmethacralyte NA Uniboard Timber Replacement NA Polycarbonate PC Polycarbonate NA Polycarbonate Hard PC Polycarbonate NA PEI-1000 PEI Polyetherimide NA PSU-1000 PSU Polysulphone NA PPSU 1000 PSSU Polysulphone NA

-

Chemical ResistanceOpen or Close

This comparative index should be considered only as roughly indicative. There are too many variables including chemical type, concentration, temperature and contact time. Even the internal stress level of plastic parts can influence the degree of Chemical Resistance and your choice of material. Inorganic Acids, bases and salts are used in a variety of concentrations, as mixtures, or on their own. For pure solutions and mixtures the pH value of the solution is a reliable tool when assessing the chemical resistance of semi-crystalline plastics. Specific Chemical Resistance information and charts are available – Please contact your local Dotmar branch for more information 1800 170 001. 20 = best resistance.

Product Product Type Value Tetco V PTFE Polytetrafluoroethylene 20 Tetron G PTFE Polytetrafluoroethylene 20 Tetron HG PTFE Polytetrafluoroethylene 20 Tetron LG PTFE Polytetrafluoroethylene 20 Tetron S PTFE Polytetrafluoroethylene 20 Tetron C PTFE Polytetrafluoroethylene 18 Tetron GR PTFE Polytetrafluoroethylene 18 Ketron PEEK-1000 PEEK Polyetheretherketone 17 Ketron PEEK-CA30 PEEK Polyetheretherketone 17 Ketron PEEK-GF30 PEEK Polyetheretherketone 17 Ketron EEK-HPV PEEK Polyetheretherketone 17 Symalit PVDF PVDF Polyvinylidenefluoride 16 Techtron HPV PPS PPS Polyphenylene Sulphide 16 Playtec PE Polyethylene 13 Polystone 300 PE Polyethylene 13 Polystone 500 PE Polyethylene 13 Polystone 7000 PE Polyethylene 13 Polystone 7000SR PE Polyethylene 13 Polystone 8000+ PE Polyethylene 13 Polystone Ezyslide 78 PE Polyethylene 13 Polystone M-Flametech AST PE Polyethylene 13 Polystone M-Slide PE Polyethylene 13 Polystone PP PP Polypropylene 13 Polystone Ultra PE Polyethylene 13 Trovidur EN PVC PVC Polyvinylchloride 12 Tetron B PTFE Polytetrafluoroethylene 12 Ertacetal C PTFE Polytetrafluoroethylene 12 Ertaylte Acetal 9 Ertaylte TX PETP Polyester 9 Duratron PBI PETP Polyester 9 Duratron T4203 & T4503 PAI PBI Polybenzimidazole 8 Duratron T4301 & T4501 PAI PAI Polyamide-imide 8 Duratron T5530 PAI PAI Polyamide-imide 8 Ertalon 4.6 PAI Polyamide-imide 8 Ertalon 66GF-30 Nylon 7 PSU-1000 Nylon 7 Ertalon 6PLA Nylon 7 Ertalon 6XAU+ Nylon 7 Ertalon LFX Nylon 7 Nylatron 703XL Nylon 7 Nylatron GS Nylon 7 Nylatron GSM Nylon 7 Nylatron MC901 Nylon 7 PEI-1000 PEI Polyetherimide 7 PPSU-1000 PPSU Polyphenylenesulphone 7 PSU-1000 PSU Polysulphone 7 Ertalon 6SA Nylon 6 Polycarbonte PC Polycarbonate 2

-

Coefficient of FrictionOpen or Close

The coefficient of friction of a material is the measure of the sliding resistance of a material over another material. In the case of thermoplastics the mating part is normally steel. When multiplying the co-efficient of friction by the perpendicular force between the two mating sliding faces, this result is the force required to slide the components across each other. Our ranking compares this "surface slipperiness" across our range of materials and is important when selecting products for use in dynamic applications.

Product Product Type Value PTFE Polytetrafluoroethylene 0.06 Polystone Matrox PE Polyethylene 0.08 0.1 Tetron LG PTFE Polytetrafluoroethylene 0.11 Tetron G PTFE Polytetrafluoroethylene 0.12 Tetron C PTFE Polytetrafluoroethylene 0.12 Orkot TXM (low friction) Orkot 0.12 Tetron B PTFE Polytetrafluoroethylene 0.13 Tetron BL PTFE Polytetrafluoroethylene NA Tetron GR PTFE Polytetrafluoroethylene 0.15 Orkot C320 TLG Orkot 0.15 Orkot TLM (Marine) Orkot 0.15 Nylatron 703XL Nylon 0.16 Polystone PG100 PE Polyethylene 0.15 Ertalyte TX PETP Polyester 0.25 Polystone M-Slide PE Polyethylene 0.15 Ertalon LFX Nylon 0.47 Polystone Ultra PE Polyethylene 0.1...0.15 Polystone 7000 PE Polyethylene 0.18 Polystone 7000SR PE Polyethylene 0.2 Polystone 7000AST PE Polyethylene 0.2 Polystone 500 PE Polyethylene 0.1...0.15 Polystone Fende PE Polyethylene 0.18 Polystone 300 PE Polyethylene 0.15 Polystone 8000+ PE Polyethylene 0.22 Ertalyte PETP Polyester 0.29 Polystone Ezyslide 78 PE Polyethylene 0.22 Polystone M-Flametech AST PE Polyethylene 0.22 Duratron T4301 & T4501 PAI PAI Polyamide-imide 0.25 Ketron PEEK-HPV PEEK Polyetheretherketone 0.38 Nylatron GS Nylon 0.3 Nylatron GSM Nylon 0.55 Ertacetal C Acetal 0.42 Nylatron MC901 Nylon 0.35 Ketron PEEK-GF30 PEEK Polyetheretherketone 0.35 Ketron PEEK-CA30 PEEK Polyetheretherketone 0.35 Ketron PEEK-1000 PEEK Polyetheretherketone 0.43 Ertalon 6XAU+ Nylon 0.35 Ertalon 6SA Nylon 0.61 Ertalon 6PLA Nylon 0.35 Symalit PVDF PVDF Polyvinylidenefluoride 0.18 Ertalon 66SA Nylon 0.41 Ertalon 4.6 Nylon NA Techtron HPV PPS PPS Polyphenylene Sulphide 0.35 Duratron PBI PBI Polybenzimidazole 0.35 Duratron T5530 PAI PAI Polyamide-imide 0.35 Duratron T4203 & T4503 PAI TFE Polytetrafluoroethylene 0.35 Ertalon 66GF-30 Nylon NA PPSU-1000 PPSU Polyphenylenesulphone NA Polystone PP PP Polypropylene NA PSU-1000 PSU Polysulphone NA PEI-1000 PEI Polyetherimide NA Tetron HG PTFE Polytetrafluoroethylene NA Polycarbonate Hard PC Polycarbonate NA Trovidure EN PVC PVC Polyvinylchloride 0.2...0.3 Polycarbonate UVX PC Polycarbonate NA Orkot C321 TL Orkot NA Uniboard Timber Replacement NA Polyurethane Urethane NA Acrylic Polymethylmethacralyte NA

-

Operating TemperatureOpen or Close

This can be measured in two categories (a) short time exposure (a few hours) and (b) continuous use over a period of 5000 /20,000 hours. Our index compares material performance in category (b). After these periods there is a decrease in tensile strength compared to original value. As with all thermoplastics the maximum service temperature also depends on the duration and magnitude of mechanical stresses on the material in application.

Product Product Type Value Duratron PBI PBI Polybenzimidazole 310 Tetco V PTFE Polytetrafluoroethylene 260 Tetron B PTFE Polytetrafluoroethylene 260 Tetron C PTFE Polytetrafluoroethylene 260 Tetron HG PTFE Polytetrafluoroethylene 260 Tetron GR PTFE Polytetrafluoroethylene 260 Tetron S PTFE Polytetrafluoroethylene 260 Tetron G PTFE Polytetrafluoroethylene 260 Tetron LG PTFE Polytetrafluoroethylene 260 Duratron T4203 & T4503 PAI PAI Polyamide-imide 250 Duratron T4301 & T4501 PAI PAI Polyamide-imide 250 Ketron PEEK-1000 PEEK Polyetheretherketone 250 Ketron PEEK-CA30 PEEK Polyetheretherketone 250 Ketron PEEK-GF30 PEEK Polyetheretherketone 250 Ketron PEEK-HPV PEEK Polyetheretherketone 250 Duratron T5530 PAI PAI Polyamide-imide 250 Techtron HPV PPS PPS Polyphenylene Sulphide 220 PPSU-1000 PPSU Polyphenylenesulphone 180 PEI-1000 PEI Polyretherimide 170 PSU-1000 PSU Polysulphone 150 Ertalon 4.6 Nylon 150 Symalit PVDF PVDF Polyvinylidenefluoride 150 Polystone PP PP Polypropylene 130 Polycarbonate PC Polycarbonate 125 Ertalon 66GF-30 Nylon 120 Ertalon 6XAU+ Nylon 120 Ertalyte PETP Polyester 115 Ertalyte TX PETP Polyester 115 Ertacetal C Acetal 115 Nylatron 703XL Nylon 105 Nylatron GSM Nylon 105 Nylatron MC901 Nylon 105 Ertalon LFX Nylon 105 Ertalon 6PLA Nylon 105 Ertalon 66SA Nylon 95 Nylatron GS Nylon 95 Polystone 7000SR PE Polyethylene 90 Polystone M-Slide PE Polyethylene 90 Ertalon 6SA Nylon 85 Polystone 8000+ PE Polyethylene 80 Polystone 7000 PE Polyethylene 80 Polystone Ezyslide 78 PE Polyethylene 80 Polystone M-Flametech AST PE Polyethylene 80 Polystone Ultra PE Polyethylene 80 Leisuretec/Playtec PE Polyethylene 80 Polystone 300 PE Polyethylene 80 Polystone 500 PE Polyethylene 80 Trovidur EN PVC PVC Polyvinylchloride 60

-

Impact ResistanceOpen or Close

Our comparison index on Impact Resistance ranks the materials out of 20 = best. The performance comparison is done at the 'most unfavourable' conditions for each material. In practice this may be harsh on some of the rankings. Impact strength decreases with decreasing service temperature. The minimum service temperature in turn being limited by the extent to which the material is subjected to Impact. Therefore materials ranked differently here at their minimum service temperature may rank very similarly for impact at their maximum service temperature in normal conditions.

Product Product Type Value Polystone 7000 PE Polyethylene Uniboard Timber Replacement 20 Polystone PP PP Polypropylene 20 Polystone PG100 PE Polyethylene 20 Polystone 500 PE Polyethylene 20 Polycarbonate PC Polycarbonate 20 Nylatron MC901 Nylon 20 Polystone M-Slide PE Polyethylene 20 Polycarbonate Hardcoat XX PC Polycarbonate 20 Polystone Fender PE Polyethylene 20 Polystone Matrox PE Polyethylene 20 Polystone P7000AST PE Polyethylene 20 Ertalon 6SA Nylon 19 Orkot C321 TL Orkot 19 Orkot C320 TLG Orkot 19 Polystone 7000SR PE Polyethylene 20 Ertalon 66SA Nylon 18 Orkot TLM (Marine) Orkot 18 Polystone 300 PE Polyethylene 12 Polystone Ezyslide 78 PE Polyethylene 18 Polystone 8000+ PE Polyethylene 18 Ertalon 6XAU+ Nylon 17 Duratron T5530 PAI PAI Polyamide-imide 17 Orkot TXM (low friction) Orkot 17 Ertalon 6XAU+ PE Polyethylene 17 Ertalon 6PLA Nylon 17 Polystone Ultra PE Polyethylene 17 Polystone M-Flametech AST PE Polyethylene 16 Nylatron GSM Nylon 16 Nylatron MC901 Nylon 20 Nylatron GS Nylon 15 Nylatron 703XL Nylon 12 Ertalon 4.6 Nylon 14 Ertalon LFX Nylon 14 Ertalon 66GF-30 Nylon 13 Tetco V PTFE Polytetrafluoroethylene 12 Duratron T4203 & T4503 PAI PAI Polyamide-imide 12 PPSU-1000 PPSU Polyphenylenesulphone 11 Playtec PE Polyethylene 11 Tetron S PTFE Polytetrafluoroethylene 11 Ketron PEEK-CA30 PEEK Polyetheretherketone 10 Ketron PEEK-1000 PEEK Polyetheretherketone 9 Katron PEEK-GF30 PEEK Polyetheretherketone 10 PEI-1000 PEI Polyetherimide 10 PSU-1000 PSU Polysulphone 10 Trovidur EN PVC PVC Polyvinylchloride >4 Symalit PVDF PVDF Polyvinylidenefluoride 20 Duratron PBI PBI Polybenzimidazole 10 Duratron T5530 PAI PAI Polyamide-imide 17 Techtron HPV PPS PPS Polyphenylene Sulphide 10 Duratron T4301 & T4501 PAI PAI Polyamide-imide 10 Ketron PEEK-HPV PEEK Polyetheretherketone 4 Tetron LG PTFE Polytetrafluoroethylene 9 Tetron G PTFE Polytetrafluoroethylene 9 Tetron HG PTFE Polytetrafluoroethylene 9 Tetron C PTFE Polytetrafluoroethylene 8 Ertacetal C Acetal 8 Tetron GR PTFE Polytetrafluoroethylene 7 Tetron B PTFE Polytetrafluoroethylene 9 Tetron BL PTFE Polytetrafluoroethylene 6 Ertalyte PETP Polyester 4 Ertalyte TX PETP Polyester 4 Acrylic Polymethylmethacralyte 4 Polyurethane Urethane NA

-

MachinabilityOpen or Close

The index is a nominal ranking out of 20 = best. Different machining processes using CNC or Manual metal-working or wood-working machinery is suitable for most thermoplastics. Because of the poor thermal conductivity and low melting point of thermoplastics heat generation must be kept to a minimum. Points to note:

- Machining Forces - lower than for metals, lower clamp forces required, lower rigidity therefore support may be needed to prevent deflection in some cases.

- Tools - Keep sharp, ensure only the cutting edge contacts material, and ensure good swarf removal.

- Coolants - Soluble oil types are generally suitable if required. Use only pure water or compressed air for PC, PEI, and PSU.

Product Product Type Value Ertalyte PETP Polyester 20 Ertacetal C Acetal 20 Ertayle TX PETP Polyester 20 Tetco V PTFE Polytetrafluoroethylene 19 Tetron S PTFE Polytetrafluoroethylene 19 Polystone Ultra PE Polyethlyene 18 Polystone 7000 PE Polyethlyene 18 Polystone 7000SR PE Polyethlyene 18 Polystone 8000+ PE Polyethlyene 18 Polystone M-Flametech AST PE Polyethlyene 18 Polystone M-Slide PE Polyethlyene 18 Ketron PEEK-1000 PEEK Polyetheretherketone 16 Ertalon 66SA Nylon 16 Ertalon 6PLA Nylon 16 Nylatron 703XL Nylon 16 Ertalon 4.6 Nylon 16 Nylatron GS Nylon 16 Nylatron GSM Nylon 16 Nylatron MC901 Nylon 16 Ertalon LFX Nylon 16 Playtec PE Polyethylene 16 Polystone 300 PE Polyethylene 16 Polystone 500 PE Polyethylene 16 Ertalon 6XAU+ Nylon 16 Duratron PBI PBI Polybenzimidazole 16 Duratron T5530 PAI PAI Polyamide-imide 16 Polystone Ezyslide 78 PE Polythylene 16 Symait PVDF PVDF Polyviylidenefluoride 16 Duratron T4301 & T4501 PAI PAI Polyamide-imide 16 Duratron T4203 & T4503 PAI PAI Polyamide-imide 16 Tetron LG PTFE Polytetrafluoroethylene 16 PPSU-1000 PPSU Polyphenylenesulphone 15 PSU-1000 PSU Polysulphone 15 Ketron PEEK-HPV PEEK Polyetheretherketone 15 PEI-1000 PEI Polyetherimide 15 Tetron G PTFE Polytetrafluoroethylene 15 Techtron HPV PPS PPS Polyphenylene Sulphide 15 Tetron HG PTFE Polytetrafluoroethylene 14 Ketron PEEK-GF30 PEEK Polyetheretherketone 13 Ertalon Nylon 13 Ketron PEEK-CA30 EK Polyetheretherketone 13 Tetron GR PTFE Polytetrafluoroethylene 12 Ertalon 6SA Nylon 12 Trovidur EN PVC PVC Polyvinylchloride 12 Tetron G PTFE Polytetrafluoroethylene 12 Polystone PP PP Polypropylene 12 Tetron C PTFE Polytetrafluoroethylene 11 Polycarbonate PC Polycarbonate 8 Tetron B PTFE Polytetrafluoroethylene 7

-

Thermal ExpansionOpen or Close

This chart compares the "Coefficient of linear thermal expansion" shown as a factor m/m.k in the table. All materials expand with changes in Temperature. Thermoplastics expand considerably more than metals (e.g. Carbon Steel 10.8 (10)-6 compared to UHMWPE 200 (10)-6 ie. approximately 10 times more).

Linear thermal expansion means the product will expand in all directions and this needs to be allowed for in design calculations. The calculation is: (given factor) x 10-6 x length x change in temperature °C.

Product Product Type M/(MxK) Polystone Ultra PE Polyethylene 200 Polystone 8000+ PE Polyethylene 200 Polystone 7000SR PE Polyethylene 200 Polystone 7000 PE Polyethylene 200 Polystone 500 PE Polyethylene 200 Polystone 300 PE Polyethylene 200 Playtec PE Polyethylene 200 Polystone M-Flametech AST PE Polyethylene 200 Polystone M-Slide PE Polyethylene 200 Polystone PP PP Polyethylene 200 Polystone Ezyslide 78 PE Polyethylene 180 Tetron G PTFE Polytetrafluoroethylene 136 Tetron B PTFE Polytetrafluoroethylene 134 Symalit PVDF PVDF Polyvinylidenefluoride 130 Tetron S PTFE Polytetrafluoroethylene 125 Tetco V PTFE Polytetrafluoroethylene 120 Tetron C PTFE Polytetrafluoroethylene 114 Tetron GR PTFE Polytetrafluoroethylene 112 Ertacetal Acetal 110 Ertalon 6SA Nylon 90 Ertalon LFX Nylon 80 Ertalon 6XAU+ Nylon 80 Nylatron MC901 Nylon 80 Ertalon 6PLA Nylon 80 Ertalon 66SA Nylon 80 Nylatron GSM Nylon 80 Ertalon 4.6 Nylon 80 Nylatron GS Nylon 80 Trovidur EN PVC PVC Polyvinylchloride 70 Polycarbonate Hard PC Polycarbonate 65 Ertalyte TX PETP Polyester 65 Polycarbonate PC Polycarbonate 65 Ertalyte PETP Polyester 60 PSU-1000 PSU Polysulphone 60 PPSU-1000 PSU Polyphenylenesulphone 55 Ertalon 66GF-30 Nylon 50 Ketron PEEK-1000 PEEK Polyetheretherketone 50 Techtron HPV PPS PPS Polyphenylene Sulphide 50 Nylatron 703XL Nylon 49 PEI-1000 PEI Polyetherimide 45 Duratron T4203 & T4503 PAI PAI Polyamide-imide 30 Ketron PEEK-GF30 PEEK Polyetheretherketone 30 Ketron PEEK-HPV PEEK Polyetheretherketone 30 Ketron PEEK-CA30 PEEK Polyetheretherketone 30 Duratron PBI PBI Polybenzimidazole 25 Duratron T5530 PAI PAI Polyamide-imide 25 Duratron T4301 & T4501 PAI PAI Polyamide-imide 25

-

StrengthOpen or Close

Engineering thermoplastics vary in their tensile strength. The method for testing the tensile strength of plastics is the same as that of metal; using a "Dog-Bone" test specimen, and recording the yield point.

Things to note when considering tensile or compressive strength – temperature, duration, speed, load and structural requirements. (Strength reduces as temperature increases, strength reduces as duration is extended.)

Product Product Type Value Duratron PBI PBI Polybenzimidazole 140 Ketron PEEK-CA30 PEEK Polyetheretherketone 130 Duratron T4203 & T4503 PAI PAI Polyamide-imide 120 Ketron PEEK-1000 PEEK Polyetheretherketone 110 PEI-1000 PEI Polyetherimide 105 Ertalon 66GF-30 Nylon 100 Ertalon 4.6 Nylon 100 Duratron T5530 PAI PAI Polyamide-imide 95 Nylon GS Nylon 92 Ertayle PETP Polyester 90 Ketron PEEK-GF30 PEEK Polyetheretherketone 90 Ertalon 66SA Nylon 90 Ertalon 6PLA Nylon 85 Ertalon 6XAU+ Nylon 83 Nylatron MC901 Nylon 82 Duratron T4301 & T4501 PAI PAI Polyamide-imide 80 PSU-1000 PSU Polysulphone 80 Nylatron GSM Nylon 78 Ertalyte PETP Polyester 76 Ertalon 6SA Nylon 76 PPSU-1000 PPSU Polyphenylenesulphone 70 Ketron PEEK-HPV EK Polyetheretherketone 75 Techtron HPV PPS PPS Polyphenylene Sulphide 75 Ertalon LFX Nylon 70 Ertacetal C Acetal 68 Nylatron 703XL Nylon 60 Acrylic Polymethylmethacralyte 60 Orkot C321 TL Orkot 60 Orkot C320 TLG Orkot 60 Orkot TLM (Marine) Orkot 60 Orkot TXm (low friction) Orkot 60 Polycarbonate Hard PC Polycarbonate 60 Polycarbonate PC Polycarbonate 70 Trovidur EN PVC PVC Polyvinylchloride 55 Symalit PVDF PVDF Polyvinylidenefluoride 50 Tetco V PTFE Polytetrafluoroethylene 36 Polystone 500 PE Polyethylene 45 Tetron S PTFE Polytetrafluoroethylene 28 Polystone PP PP Polypropylene 33 Tetron HG PTFE Polytetrafluoroethylene 25 Polystone PG100 PE Polyethylene 24 Polystone 300 PE Polyethylene 45 Tetron B PTFE Polytetrafluoroethylene 16 Polystone 8000 PE Polyethylene 23 Polystone 7000 PE Polyethylene 45 Tetron BL PTFE Polytetrafluoroethylene 20 Polystone Matrox PE Polyethylene 45 Polystone Ezyslide 78 PE Polyethylene 20 Polystone Ultra PE Polyethylene 45 Polystone M-Slide PE Polyethylene 20 Polystone 7000SR PE Polyethylene 20 Polystone 8000+ PE Polyethylene 45 Polystone M-Flametech AST PE Polyethylene 18 Uniboard Timber Replacement 18 Tetron C PTFE Polytetrafluoroethylene 14 Tetron G PTFE Polytetrafluoroethylene 17 Tetron GR PTFE Polytetrafluoroethylene 17 Tetron LG PTFE Polytetrafluoroethylene 11.7 PVC Polyvinylchloride >55 Playtec PE Polyethylene NA Polyurethane Urethane NA

-

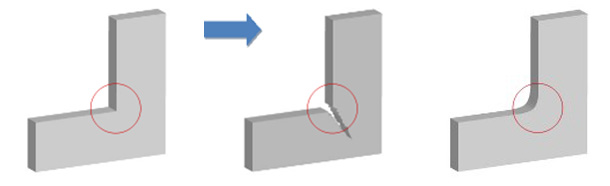

Notch SensitivityOpen or Close

Some grades of engineering plastics have exceptional impact resistance and very good load carrying capacity. However the performance of materials can be greatly compromised by incorrect design and machining parameters that result in sharp corners on finished parts.

A sharp corner on a machined part can be a "weak" point where cracking will most likely occur. Sharp corners not only reduce the impact resistance of a part, but also allow for stress concentration to occur at that point. This will result in premature failure on load carrying plastic parts.

Following correct design and machining guidelines is imperative, and even though minimising sharp corners may make the machining operation more difficult, it is crucial to long term application success.

Edges of sheet materials used in glazing applications (eg. PC - Makrolon Polycarbonate) must also be free of sharp notches or cracks. Parts machined with sharp corners could eventually stress crack. Rounded corners are correct parameters for machining.

Dotmar offer in-house technical support and thermoplastic applications advice. For correct design and machining guidelines contact our technical experts.

-

FlammabilityOpen or Close

The Flammability Oxygen Index is an economical and precise quality control test of combustible materials. The technique measures the minimum percentage of oxygen in the test atmosphere that is required to support combustion.

Product Flammability Oxygen Index Duratron PBI 58 Duratron T5530 PAI 50 Duratron T4203 & T4503 PAI 45 PPSU 1000 44 Symalit PVDF 44 Techtron HPV PPS 44 Duratron T4301 & T4501 PAI 44 Ketron PEEK HPV 43 Ketron PEEK CA30 40 Ketron PEEK GF30 40 Ketron PEEK 1000 35 Polysulphone PSU 1000 30 Nylon Ertalon 66SA 26 Nylon Nylatron GS 26 Nylon Ertalon 6SA 25 Nylon Ertalon 6PLA 25 Nylon Ertalon 6XAU 25 Nylon Nylatron GSM 25 Nylon Nylatron MC901 25 Polyester PETP Ertalyte 25 Polyester PETP Ertalyte TX 25 Nylon Ertalon 4.6 24 Nylon Nylatron 703XL 20 Acetal Ertacetal C 15 Polyetherimide PEI 1000 15

-

Electrical PropertiesOpen or Close

Certain thermoplastics are good electrical insulators and offer freedom of design in electrical applications. This table is an indication of which engineering plastic will offer the best or worst performance when used in applications where electrical insulating properties is required.

Please refer to the Technical section of the Dotmar website for explanations of the electrical properties of thermoplastics or contact Dotmar if you require specific technical data.

- - Volume resistivity

- - Surface resitivity

- - Dielectric constant

- - Dielectric strength

- - Dissipation factor

- - Arc resistance

Please note: Electrical properties may also be changed by environmental conditions such as moisture and/or temperature.

Product Product Type Value Tetco V PTFE Polytetrafluoroethylene 20 Tetron GR PTFE Polytetrafluoroethylene 20 Tetron S PTFE Polytetrafluoroethylene 12 Polystone PP PP Polypropylene 11 Polystone 7000 PE Polyethylene 8 Polystone 300 PE Polyethylene 6 Ertalon 66GF-30 Nylon 6 PSU-1000 PSU Polysulphone 6 Ertalon 6XAU+ Nylon 6 Duratron T5530 PAI PAI Polyamide-imide 6 Polycarbonate PC Polycarbonate 6 Ertalon 66SA Nylon 6 PEI-1000 PEI Polyetherimide 6 Nylatron GS Nylon 5 Ertalon 4.6 Nylon 5 Ertalon 6PLA Nylon 5 Nylatron MC901 Nylon 5 Ertalon 6SA Nylon 5 Ketron PEEK-1000 PEEK Polyetheretherketone 5 Ketron PEEK-GF30 PEEK Polyetheretherketone 5 Techtron HPV PPS PPS Polyphenylene Sulphide 5 Duratron T4203 & T4503 PAI PAI Polyamide-imide 5 Nylon GSM Nylon 5 Ertalyte PETP Polyester 5 Duratron PBI PBI Polybenzimidazole 5 Ertalon LFX Nylon 5 Ertalyte TX PETP Polyester 4 Ertacetal C Acetal 4 Symalit PVDF PVDF Polyvinylidenefluoride 4 Tetron G PTFE Polytetrafluoroethylene 3

-

Fatigue ResistanceOpen or Close

The behaviour of materials subjected to repeated cyclic loading in terms of flexing, stretching, compressing or twisting is generally described as fatigue. Such repeated cyclic loading eventually constitutes a mechanical deterioration and progressive material degradation. Failure life is defined as the number of cycles of deformation required to bring about the failure of the test specimen under a given set of oscillating conditions.

Fatigue data are generally reported as the number of cycles to fail at a given maximum stress level. At high stress levels materials tend to fail at lower number of cycles and at low stresses the materials can be stressed cyclically for a greater number of times and in some cases the failure point is virtually impossible to establish.

Two basic types of tests have been developed to test fatigue behavior in thermoplastics:

- - Flexural Fatigue Test

- - Tensile Fatigue Test

For more information on Fatigue Resistance and Plastics, please contact your nearest Dotmar Technical Representative.

-

DensityOpen or Close

Density is calculated by dividing the mass of the material by the volume and is normally expressed in g/cm3. Specific Gravity (SG) is defined as the ratio of density of the material to the density of water (1 g/cm3) at a specified temperature.

A Specific Gravity of less than 1 means that the material will float in water.

Product Measure Density PTFE Tetron B g/cm3 3.9 PTFE Tetron BL g/cm3 2.34 PTFE Tetron HG g/cm3 2.27 PTFE Tetron G g/cm3 2.22 PTFE Tetron S g/cm3 2.18 PTFE Tetron GR g/cm3 2.2 PTFE Tetco V g/cm3 2.17 PTFE Ticomp S g/cm3 2.1 PTFE Tetron C g/cm3 2.17 Symalit PVDF g/cm3 1.79 Duratron T5530 PAI g/cm3 1.61 Ketron PEEK GF30 g/cm3 1.51 Polyvinylchloride Trovidur EN PVC g/cm3 1.47 Ketron PEEK HPV g/cm3 1.45 Duratron T4301 & T4501 PAI g/cm3 1.45 Polyester PETP Ertalyte TX g/cm3 1.44 Techtron HPV PPS g/cm3 1.43 Acetal Ertacetal C g/cm3 1.41 Duratron T4203 & T4503 PAI g/cm3 1.41 Ketron PEEK CA30 g/cm3 1.4 Polyester PETP Ertalyte g/cm3 1.39 Ketron PEEK 1000 g/cm3 1.31 Duratron PBI g/cm3 1.3 Orkot TLM Marine g/cm3 1.3 Orkot TXM Marine g/cm3 1.3 PPSU 1000 g/cm3 1.29 Nylon Ertaln 66GF30 g/cm3 1.29 Polyetherimide PEI 1000 g/cm3 1.27 Orkot C320 (TLG) g/cm3 1.3 Orkot C321 (TL) g/cm3 1.3 Polysulphone PSU 1000 g/cm3 1.24 Polycarbonate UVX g/cm3 1.2 Polyurethane g/cm3 1.2 Acrylic g/cm3 1.2 Nylon Ertalon 4.6 g/cm3 1.18 Nylon Nylatron GSM g/cm3 1.16 Nylon Ertalon 6PLA g/cm3 1.15 Nylon Ertalon 6XAU g/cm3 1.15 Nylon Nylatron GS g/cm3 1.15 Nylon Nylatron MC901 g/cm3 1.15 Nylon Ertalon 6SA g/cm3 1.14 Nylon Ertalon 66SA g/cm3 1.14 Nylon Ertalon LFX g/cm3 1.14 Nylon Nylatron 703XL g/cm3 1.11 Polyethylene Polystone M-Flametech g/cm3 0.98 Polyethylene PE Nuvex Playboard g/cm3 0.97 Polyethylene PE Nuvex Leisureboard g/cm3 0.97 Polyethylene PE Nuvex Saniboard g/cm3 0.97 Polyethylene Polystone Ezyslide 78 g/cm3 0.96 Polyethylene Polystone P8000+ g/cm3 0.96 Polyethylene Polystone PG100 g/cm3 0.96 Polyethylene Polystone P500 g/cm3 0.96 Polyethylene Polystone P300 g/cm3 0.95 Polyethylene Polystone Cutrite g/cm3 0.95 Polyethylene Polystone M-Slide g/cm3 0.95 Polyethylene Polystone Fender g/cm3 0.95 Polyethylene PE Nuvex Boatboard g/cm3 0.95 Polyethylene Polystone P7000AST g/cm3 0.95 Polyethylene Polystone P7000 g/cm3 0.93 Polyethylene Polystone Ultra g/cm3 0.93 Polyethylene Polystone P7000SR g/cm3 0.93 Polyethylene Polystone Matrox g/cm3 0.93 Polypropylene Polystone PPH g/cm3 0.92 Polyethylene PE Uniboard Eco g/cm3 0.75 Uniboard g/cm3 0.70 Polypropylene Uniboard Standard g/cm3 0.65 Polypropylene Uniboard Ultrastiff g/cm3 0.57/0.68

-

UV ResistanceOpen or Close

Thermoplastics can be subject to degradation if environmental factors are not taken into account. Environmental conditions that could be damaging to plastics include exposure to UV, moisture, chemicals, temperature and oxidation. Not all grades of thermoplastics are suitable for outdoor applications. Materials that are not UV stable will change both in appearance and molecular structure when exposed to UV, and over time can become brittle, crack, change colour, warp etc.

Careful consideration should be taken to ensure correct material selection for not only the application but also the environment in which the material is expected to perform.

- - How long will the material / part be expected to last?

- - To what extend or time period will the material / part exposed to UV? (eg. direct UV early morning/late afternoon or longer periods of exposure during the high risk UV times of the day.) What other environmental factors impact on the application?

- - Exposure to other harsh environmental factors, (eg. water, temperature extremes, chemicals etc.) can impact on overall material performance and contribute to degradation.

This table is a quick guide to assist with product suitability under normal working conditions with exposure to direct sunlight. If you have any questions about environmental effects on thermoplastics, please contact your nearest Dotmar office for assistance.

(Standard grades of thermoplastics can be modified with UV stabilisers to increase UV resistant properties.)

Product Resistance Acetal - Ertacetal YES - Black NO - Natural Ketron PEEK YES NOTE: Most unfilled, natural grades of nylon will eventually degrade upon exposure to UV.

Carbon filled grades provide better UV stability and can be used in selected applications

where UV resistance is required.Nylon Ertalon 4.6 NA Nylon Eratlon 66GF30 NA Nylon Ertalon 66SA NA Nylon Ertalon 6PLA NA Nylon Ertalon 6SA NA Nylon Ertalon 6XAU NA Nylon Ertalon LFX NA Nylon Nylatron 703XL NA Nylon Nylatron GS NA Nylon Nylatron GSM NA Nylon Nylatron MC901 YES Orkot C320 (TLG) YES Orkot C321 (TL) YES Orkot TLM Marine YES Orkot TXM Marine YES Duratron T4203 & T4503 PAI YES Duratron T4301 & T4501 PAI YES Duratron T5530 PAI YES (PC is traditionally not UV stable. Dotmar's Polycarbonate

PC sheet is a high quality, UV stabilised material.)Polycarbonate UVX YES Polyester PETP Ertalyte NO Polyester PETP Ertalyte TX NO Polyetherimide PEI 1000 NA Natural polyethylene grades will degrade upon exposure UV. Discoloration will occur

and material will become brittle. Black sheet provides better UV stability. Dotmar's Polystone

black grades offer exceptional UV stability for the harsh Australian climatic conditions.Polyethylene PE Nuvex Boatboard YES Polyethylene PE Nuvex Leisureboard YES Polyethylene PE Nuvex Playboard YES Polyethylene PE Nuvex Saniboard YES Polyethylene PE Uniboard Eco YES Polyethylene Polystone Ezyslide 78 NA Polyethylene Polystone Fender YES Polyethylene Polystone Matrox YES Polyethylene Polystone M-Flametech YES Polyethylene Polystone M-Slide YES Polyethylene Polystone PG100 YES Polyethylene Polystone P300 YES - Black NO - Natural Polyethylene Polystone P500 YES - Black NO - Natural Polyethylene Polystone P7000 YES - Black NO - Natural Polyethylene Polystone P8000+ YES Polyethylene Polystone Ultra Moderate UV Resistance Polyethylene Polystone PP-H Moderate UV Resistance Polyethylene Uniboard Standard YES Polyethylene Uniboard Ultrastiff YES Polysulphone PSU 1000 YES Polyvinylchloride Trovidur EN PVC Moderate UV Resistance PPSU 1000 YES Techtron HPV PPS YES Tetron PTFE YES Tetron PTFE YES

-

Creep ResistanceOpen or Close

Creep resistance can be defined as a material's ability to resist any kind of distortion when under a load over an extended period of time. For optimum performance and maximum lifetime, engineering plastics, which are subjected to long-term loading, should have a high creep resistance (ie. low plastic deformation under load).

Creep behaviour is also one of the factors that limit the maximum application temperature of a material. This table is an indication of which engineering plastic offer the best or worst performance, with 1 = Best in terms of Creep Resistance.

Product Product Type Value Ketron PEEK-HPV PEEK Polyetheretherketone 1 Ertalyte PETP Polyester 1 Ertalyte TX PETP Polyester 1 Ertalon 66GF-30 Nylon 1 Ketron PEEK-1000 PEEK Polyetheretherketone 2 Ertacetal C Acetal 2 Duratron PBI PBI Polybenzimidazole 2 Duratron T4203 & T4503 PAI PAI Polyamide-imide 2 Ertalon 4.6 Nylon 2 Ertalon 66SA Nylon 2 Ertalon 6PLA Nylon 2 Ertalon 6XAU+ Nylon 2 Nylatron GS Nylon 2 Nylatron GSM Nylon 2 Nylatron MC901 Nylon 2 Trovidur EN PVC PVC Polyvinylchloride 3 PEI-1000 PEI Polyetherimide 3 PSU-1000 PSU Polysulphone 3 Ertalon 6SA Nylon 3 Polycarbonate PC Polycarbonate 3 Ertalon LFX Nylon 4 Tetron C PTFE Polytetrafluoroethylene 5 Tetron GR PTFE Polytetrafluoroethylene 6 Tetron B PTFE Polytetrafluoroethylene 8 Tetron GR PTFE Polytetrafluoroethylene 12 Tetron S PTFE Polytetrafluoroethylene 14 Polystone 7000SR PE Polyethylene 14 Polystone 8000+ PE Polyethylene 14 Symalit PVDF PVDF Polyvinylidenefluoride 16 Polystone 7000 PE Polyethylene 18 Polystone PP PE Polyethylene 18 Polystone Ultra PE Polyethylene 18 Polystone 300 PE Polyethylene 19 Polystone 500 PE Polyethylene 20